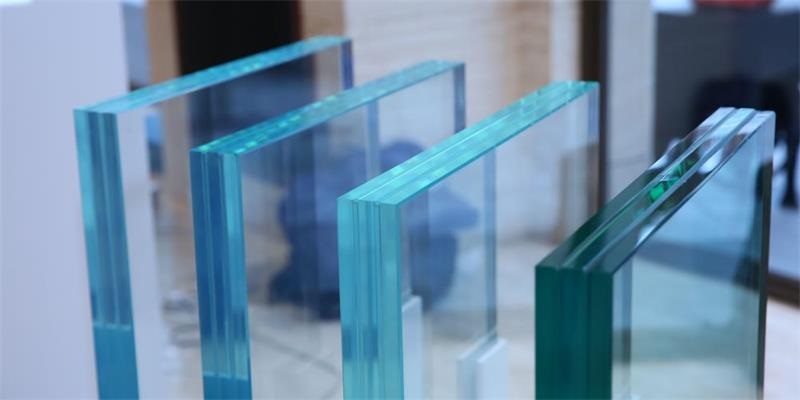

Low iron glass is a kind of ultra-transparent low-iron glass, also known as ultra clear glass. It is a high-quality, multi-functional new type of high-grade glass, with a light transmittance of more than 91.5%, and it is crystal clear, High and elegant characteristics, it is known as the “Crystal Prince” of the glass family.Low iron glass has all the machinable properties of high-quality float glass, has superior physical, mechanical and optical properties, and can be subjected to various deep processing like other high-quality float glass.,but what’s the difference between normal glass and low iron glass?Here we introduce 6 difference.

- Low iron glass has much lower glass self explosion ratio.

As we know,the Nis inside glass will cause glass spontaneous breakage.The glass contains nickel sulfide crystals. NiS (nickel sulfide) has a phase transition process at 379 ° C. When the high-temperature α-NiS crystal system is changed to the low-temperature β-NiS crystal system, the volume expands by 2% to 4%. And the surface is rough. If these impurities are in the tensile stress zone of the tempered glass, volume expansion may cause spontaneous bursting.

Glass deep processing enterprises will have heat soak test on after the tempering process, effectively reducing the probability of self-explosion.

The Nickle mainly exist in the glass raw materials,and the float glass production lines, low iron glass raw materials source are quite different from the normal clear glass with much stricter requirement,the raw materials are more pure,which will decrease the tempered glass spontaneous breakage ratio,which can even compete with the heat soaked tempered glass breakage ratio, 3‰ is believed to be a reasonable rate.

- Low iron glass has much pure color.

Normal clear glass color is slightly green,especially thick glass panel,15mm,19mm,the green color is more obvious,it’s caused by the iron content of the raw materials.Since the iron content in the raw material is only 1/10 or even lower than that of clear glass, low iron glass has less absorption of the green band of visible light than ordinary glass, ensuring the pure and light glass color.

- Low iron glass has higher light transmittance & solar coefficient.

Low iron glass allows much higher light transmittance and allows more solar energy transmitted the glass,that’s the reason,greenhouse,solar panels,photovoltaic panels, and museum glass prefer low iron glass to get more solar energy and more clear appearance .

Below chart shows the difference between ultra glass & clear glass.

- Low iron glass has lower UV transmittance.

Low iron glass allows fewer UV penetrate the glass and protect the interior furniture,and fabrics.

Normal clear glass has about 90% UV transmittance between 150-3300nm wave band,it cannot stop the UV penetrate the glass,below table shows the low iron glass Ultraviolet of low iron glass.

- Production Difficulty

The production difficulty of low iron glass is much higher than clear glass because of strict raw materials and production lines,as well as glass production technology.that’s the reason only few float glass manufacturers can produce low iron glass.The manufacturers include PPG, Saint Gobain Glass,Pilkington Glass,AGC,China CSG,XYG,Jinjing.

China SYP tried to produce low iron glass several years ago but failed because the glass quality is not stable.

Extend:Jinjing upgraded low iron Glass-Zhichun

- Low iron glass price is much higher

In China,low iron glass price is 50% higher than normal clear glass,once been made into processed glass,the price difference is even higher.

In 2020 May, clear glass & low iron glass price was USD 235/MT and USD340/MT.

Now 2021,May, the price all increased and reached USD 470/MT and USD 650/MT.

Learn more about China glass price increase in 2021.May.

The superior visual performance of ultra clear glass will greatly improve the function and decorative effect of processed glass products. Therefore,ultra clear glass has a wide range of application and broad market prospects.

It’s widely used in high-end buildings, high-end glass processing and solar photovoltaic curtain walls, as well as high-end glass furniture, decorative glass, imitation crystal products, lamp glass, precision electronics (copiers, scanners), special buildings, etc.

Main China low iron glass manufacturer:

For Building application: Jinjing Glass, China South Glass, Xinyi Glass, Taiwan Glass,Kibing Glass

For solar applications: Jinjing glass, Ancai Glass,Flat Glass, Xiuqiang Glass,Xinfuxing Glass.

Welcome contact us if you got any low iron processed glass requirement.

Contact us:

Qingdao Morn Building Materials Co.,Ltd

China HQ: Room A304,Shengxifu Road,NO.209 Weihai Road,Shibei District,Qingdao,China,266024

Sales Email: marketing@cnmorn.com

Technical support: han@cnmorn.com Mobile/Wechat: 0086-17705464660 Website:https://www.cnmorn.com/ https://www.mornglass.com/